Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 20 Sets Per Months

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

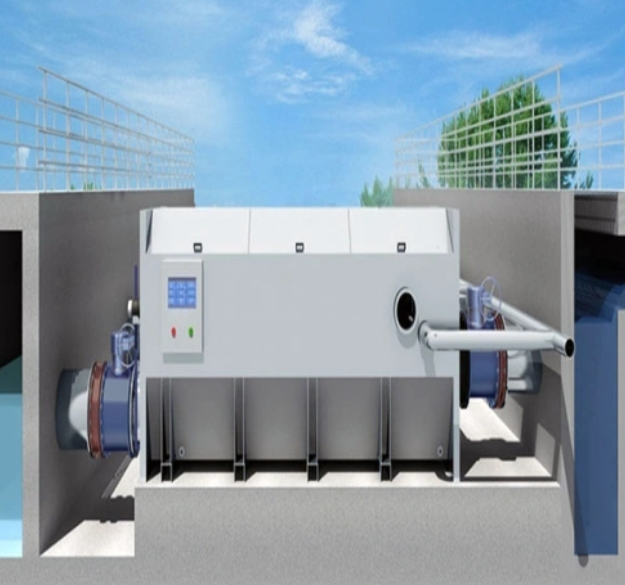

LDT Series Rotary Drum Type Thickeners

Drum Sludge Thickener Definition

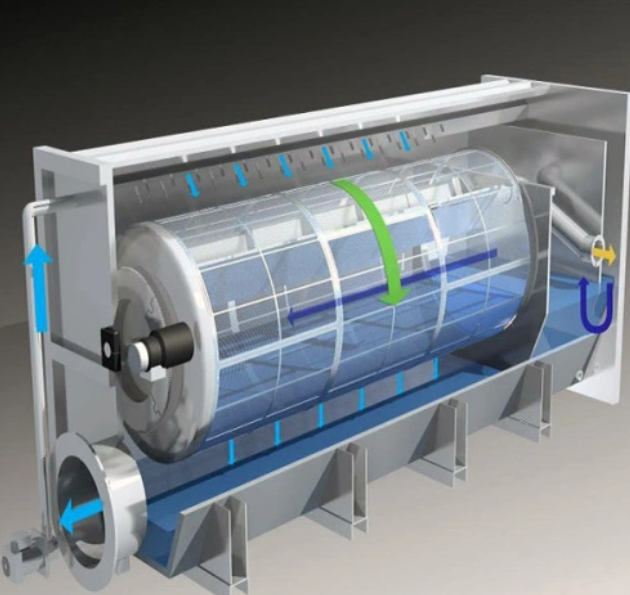

The Precision Rotary Drum Filter is a precision Suspend Solid Interception machine Under gravity or pressure difference or Centrifugal Force to Separate Sludge and Water During Filtration.

Drum Sludge Filter Working Principle

The Flocculated Sludge Which Enters Its Drum to Thicken The Sludge Content from 0.8%-1% into 3.5%-11% after Draining Out Its Most Free Water Under Function of Gravity and Centrifugal Force, Thus to Reduce The Sludge Fluidity So as to provide the condition for the Preliminary Thickening.

Drum Water Sludge Purifier Feature and Characteristic

- Simple Structure with Easy Maintenance Design

- Safe and Reliable Performance

- Independent Filtration Mesh Flexible for Dispatching and Easy change after 3 years long life time running.

- Strong Impact-load Resistance under Condtion of TSS≤40 mg/L

- Large Treated Capacity and High Efficiency

- Suspend Solid Recycling Ratio Over 86%

- Little Room with Little Cost and Auto Protection Device

- Small Water Head Lost≤300mm

- Each Drum Set Each Reducer (0.37KW) Under SS304 Structure

- With Dispatchable Cover and Cloth Continuous Washing System

- Drum Diameter Range: 400-1400mm

- It Can Be mounted on Belt Filter Press To Save Room

- No Need Extra Flocculants.

- Unique Use Can With Unique Control Box

Applicant: Sludge Preliminary Thickening or Solid Liquid Separation

- Aquaculture

- Paper Pulp Separation

- Fiber Water Purification

- Chemistry

- Food Industry

- Plastic Industry Sludge Water

- Mining Slurry Water Separation

- Starch Processing

- Alcohol or Wine Processing Raw Material Recycling

- Tap Water Pre-Filtration

- Rainy Water Recycling

- City Sewage Treatment Plant

- Pharmacy

- Electronica Plating

- Leather, Dyeing and Printing

- Metallurgy

- Slaughter House

Specification and Model Selection

Model | Capacity (M3/h) | Dry Sludge (kg/h) | Power (kW) | Dimension (L*W*H) mm |

LDT-5 | 6 | 40-70 | 1.75 | 2710*940*1210 |

LDT-10 | 12 | 90-120 | 1.75 | 2710*1040*1350 |

LDT-20 | 20 | 150-220 | 2.0 | 3350*1060*1490 |

LDT-30 | 30 | 240-310 | 2.75 | 3450*1080*1540 |

LDT-40 | 40 | 260-420 | 3.25 | 3550*1130*1600 |

LDT-50 | 50 | 290-510 | 3.25 | 4050*1130*1850 |

LDT-60 | 60 | 360-600 | 4.75 | 3500*1800*1540 |

LDT-80 | 80 | 540-900 | 4.75 | 3650*1900*1600 |

LDT-100 | 105 | 620-1250 | 5.0 | 4150*1900*1850 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.