Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 10 Sets Per Three Months

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

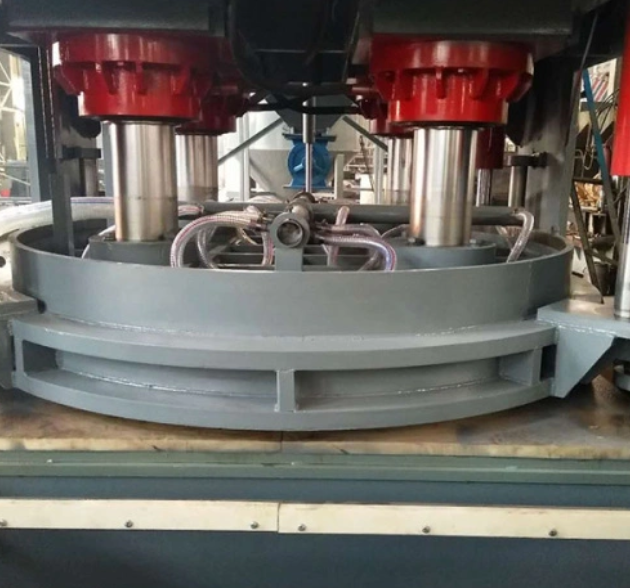

Loren LHP Series Hammer Sludge Press

Municipal Stp Sludge Dehydrator Definition

It Is a A high (Fuel) Oil Sludge Pressing Machine with one or dual-acting oil cylinders as the main pressing part, which is preheated and then pressed, The Outlet Dry Sludge Moisture Can be 45%-55%

Fuel Sludge Dryer Feature

-Special Design for Oily Sludge De-watering or Recycling or Drying

-High Oil Yield Ratio and Sludge Proclivities

-Economical and Reasonable Design

-Easy Maintenance

-Small Footprint

-Simple Operation

-Highly Automation

-Little Energy Consumption

-Little Labor Work

-Cost Saving

Hammer Style Oil Sludge Compactor Working Principle

The Device Adopts The Principle Of Cylinder-Piston. The Special Filters At Both Ends Of The Equipment Use The Thrust Of The Oil Cylinder To Squeeze The Water And Separate The Mud And Water. Used In Secondary Pressing Of Municipal Sludge

Main Configuration of LHP-2000 Large Municipal Sludge Dryer

Dry Sludge Yield Volume:30-50 Metric Tons Per Day

Max. Run Pressure:12000KN

Motor Power:15 KW

Compacting Dimension DN1500-DN2200MM Optional Choose

Compacting Part Material :Stainless Steel 304

Dry Sludge Moisture:35-45%

System Dimension:6000 *2300 * 3200mm

Resistant Working Temperature: 100-150℃

Applicant

-Industrial Sludge

-Municipal STP Sludge

-Oily Sludge Field

-Other Materials with moisture

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.