Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 15 Sets Per three Months

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

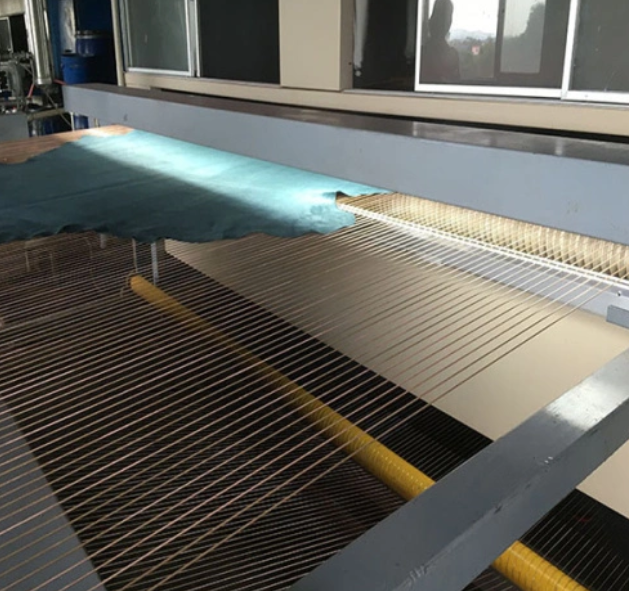

LCLD Series Continuous Leather Dehumidification And Drying Machine Continuous Dehumidifier For Leather Processing

Innovative Technology of Steam-Source Low Temperature Dehumidification Machine

-Solve Technical Bottlenecks Between Frosting And Poor High Temperature Performance

-Dehumidification Performance Ratio: ≥(SMER) 3kgs.HO2/KW.H

-Patent for Intermediate Heat Exchange Cooling Dehumidification

-Patent for Temperature Echelon Utilization Technology

-Patent for Double-effect, Triple-Effect Dehumidification Technology

-Larger Dryer Temperature range:From 15-80℃ with Intake Temp. 95℃ to meet Cool Air Drying, Heat Air Drying and Alternative Cool and Hot Air Dehumidification

-Adopts Advanced Refrigerant Recovery Technology Improve Compressor Cooling Efficiency to Save Running Cost by way of Energy Saving Machine to exchange the Low Pressure Air with High Pressure Air to heat the low pressure air and cool the refrigerant liquid

-Module Design to fit for upgrading and maintenance

-PLC Intelligent Control of single or multiple sets together with Remote Control

-Widely Applicant Field of industrial, ETP, food and Pharmacy etc.

Definition of Continuous refrigerant Leather Drying Machine

It Is a Device That Uses The Refrigeration System To Cool And Humidify

The Hot And Humid Air While Recovering The Air Moisture By The Heat

Pump Principle To Condense The Latent Heat.

Dehumidification Heat Pump = Dehumidification Drying+ Heat Pump (Energy Recovery) Combined

The Final Applicant of Dyed Sludge Particles Can Be Used As

-Fertilizer

-Fuel

-Incineration

-Building Materials

-Bio Fuel

-Landfill Covering Soil

-Land Utilization Etc.

Feature

-Can Dry Leather Moisture Below 15%

-Water Vapor Is Condensed At 5℃

-Continuously Closed Drying Process Assure Safety Below 50℃ with Oxygen Volume Lower Than 12%

-No Odour with Maximum Drying Temperature As 50℃

-One Fifth of Traditional Drying Machine Taken Up Area

- 1KW.H Power Can Evaporate 3L Water Compared that of Traditional one is 3KW.H

- Easy and Convenient Operation

-The Mesh Belt Speed Is Controlled By Frequency Conversion, And The Moisture Content Of The Sludge Discharge Is Adjustable (10-30%)

-Small Footprint: 3.5 Square Meters Per Ton Water Evaporation

- No Pollutant Discharged Out

-No Noise Contamination

-Globally No Influenced By Outside Temperature and Circumstance Change

-Moderate and Low Temperature Drying Yield Out Better Quality Dry Sludge

-The Sanitation Condition of Drying Process is Excellent

-Fit for Inert Environment Changes,

-Fit For Inflammable & Explosive, Volatile And Toxic Materials Occasions

-Ventilation Temperature Can Reach 95℃

- PLC Touch Screen Control

-Lower Investment and Lower Maintenance Charge

Working Principle

Utilizing The Dehumidification Principle Of The Low-Temperature Heat Pump, The Sludge Is Dried By Convective Hot Air, So That The Moisture In The Material Absorbs Heat And Evaporates Into The Air To Achieve The Purpose Of Reducing The Moisture Content. It Use The Refrigeration System To Cool The Hot And Humid Air Below The Dew Point To Precipitate Moisture, And Then Heat The Air Through Multiple Heat Recovery Technologies To Keep The Moisture In The Sludge Evaporating,

Evaporation-Dehumidification-Heating-Evaporation-Re-Dehumidification,

In Fact It Is Equal To The Organic Combination Of Dehumidification Heat Pump + Heat Recovery Technology + Material Delivery System.

Applicant

- Leather Processing Plant -ETP , STP

-Special Wet Leather Drying System

-Finished Leather Humidification System

-Other Leather Related Industry

-Dyeing and Printing Sludge

-Dangerous or Harmful Sludge

Model Selection & Specification Table

LCLD Series Low Temperature Continuous Leather Dehumidifier Dryer

Model | LCLD-4000 | LCLD-8000 |

Min.Dehumidification Volume (Air Intake 60℃,45% RH) | 100 kg/h | 200 kg/h |

Max.Dehumidification Volume | 111 kg/h | 222 kg/h |

Refrigerant | R134a | R134a |

Dry Temperature | 65℃ | 65℃ |

Drive Power | 45KW | 89 KW |

Control Box | PLC | PLC |

Weight | 1750kg | 2100kg |

Different Dry Sludge Quantity Table Under Different Moisture

Sludge Moisture(%) | Sludge Volume Per Ton ( M3) | Sludge Moisture(%) | Sludge Volume Per Ton ( M3) |

99.9 | 200 | 60 | 0.5 |

98 | 10 | 50 | 0.4 |

90 | 2 | 40 | 0.33 |

85 | 1.33 | 30 | 0.29 |

802 | 1.0 | 20 | 0.25 |

70 | 0.67 | 10 | 0.22 |

60 | 0.5 | 5 | 0.21 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.