Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 50 Sets Per Three Months

:

:

:

:

:

:

:

:

:

:

:

:

:

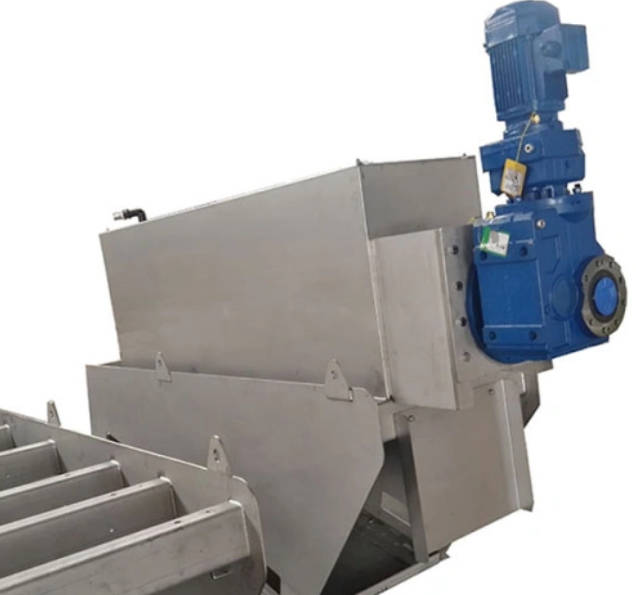

Ldl Series Spiral Mud Dehydrator

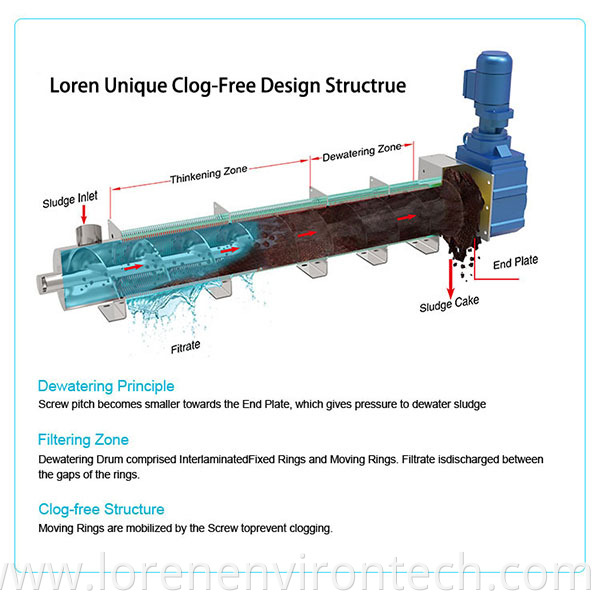

Loren Continuous Multiple Screw Dewatering Machine Definition

It's a New Type Clog-Free Solid-Liquid Separation Equipment By Utilizing Strong Screw Extrusion Pressure Between Screw Diameter And Pitch Change Under Tiny Gap Between Moving Rings And Fixing Rings To Realize Separation Or Sludge Dewatering Under Full Auto Control Plc Control Panel With Its Auto Self-Cleaning System.

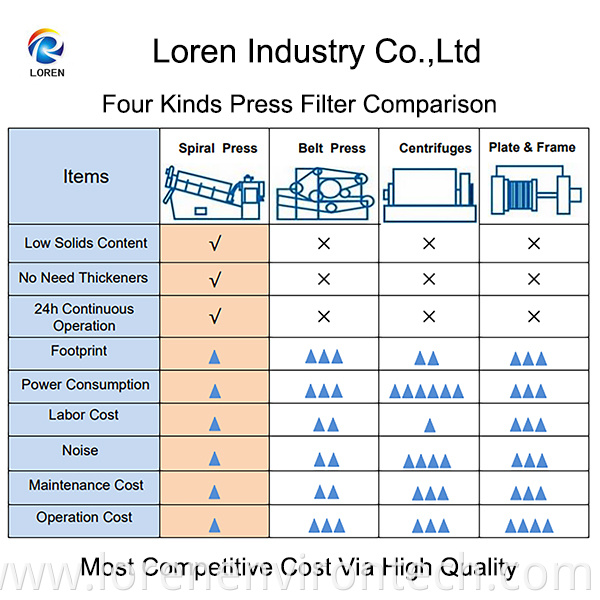

It Can Replace Traditional Filter Press Like Belt Press Filter , Frame Plate Press, Volute Decanters In Some Special Field And Condition Sites.

Multiple Disc Ring Spiral Dewatering Machine Feature & Merit

-Lower Run Cost: 40% of Belt Press & 20% of Volute Decanter

-Energy Saving: Less Than 5% of Centrifuge Decanter

-Low Speed Run with No Vibration and Noise

-Little Water Consumption: 0.1% of Belt Filter Press

-Chemical Saving: Around 60%

-Compact Design: Save Site Room

-Investment Saving: 60%

-Clog-Free Performance: Fit for Sludge with oil, Grease and Fiber Perfectly

-No Filter Cloth , No Need High Pressure Back Washing

-PLC Control with More Accurate Performance and Convenience

-Applied in Many Raw Sludge Moisture Range: 95%-99%

-Concentrated Sludge Moisture Adjustable Range: 90%-96%

-High Thickening Efficiency

-Enclosure Working with No Secondary Odor or VOCS Generated

-Little Easy-Damaged Parts, Little Maintenance Fee

-Stainless Steel Module Structure Make It Run In A Long Life Time

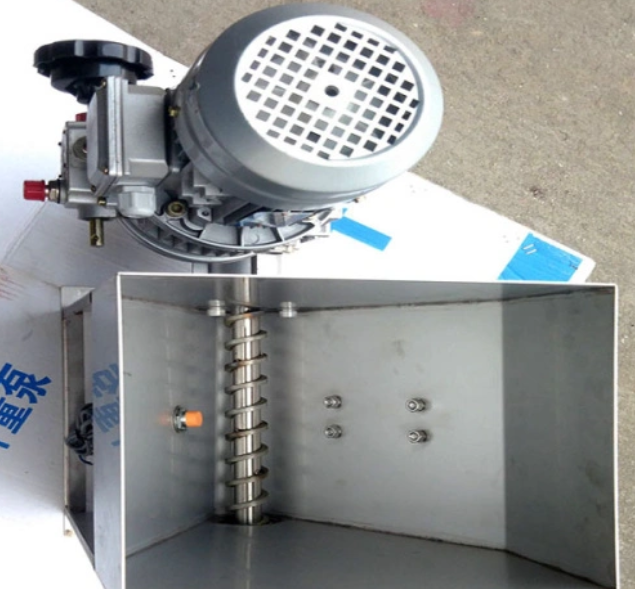

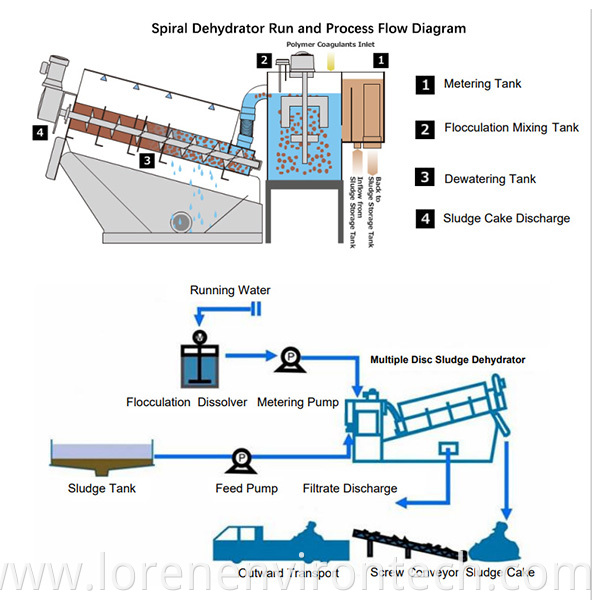

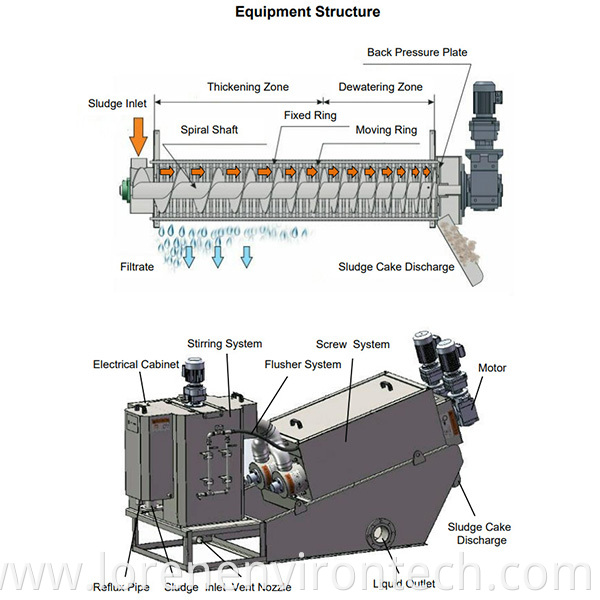

The Multiple Disc Spiral Sludge Filter Press Working Principle

The Wastewater Is Pushed Into The Spiral Dehydrator,The Sludge Will Bear Heavier Pressure Of The Helical Aixs Blades And Began To Carry On Dewatering After Continuously Being Moved To The Outlet Port Of The Sludge Cake Due To The Gap Among The Helical Blades Gradually Becoming Narrower And The Water Will Then Comes Out From The Gap Between Fixed Plates And Moving Plates.

Multiple Disc Sludge Dewatering Volute Screw Press Applicant

-Hotel and Restaurant

-Building Material Shops

-Machinery Repair Shops

-Agriculture

-Construction Works

-Municipal Sewage Treatment Plant

-Petroleum Refinery Plant

-Brewing

-Tannery

-Coal chemical industry

-Ore Dressing

-Pharmaceutical Factory

-Paper Making Factory

-Dyeing and Printing

-Sugar Processing Plant

-Food Processing

-Slaughter House

-As Deep Dehumidifier Pre-treatment for Ultra High Pressure Press or Membrane Filter Press

-Replace The Sludge Thickener Tank as Pretreatment of Sludge Reduction

Main Technique Parameter & Model Selection ofScrew Press Dewatering Filter Machine for Different Sludge

Model | Low Density DS (kg/h) | High Density DS (kg/h) | 10K mg/l | 20K mg/l | 25K mg/l | 50K mg/l |

LDL131 | 5 | 10 | 0.5 | 0.5 | 0.4 | 0.2 |

LDL132 | 10 | 20 | 1.0 | 1.0 | 0.8 | 0.4 |

LDL 251 | 15 | 30 | 1.5 | 1.5 | 1.2 | 0.6 |

LDL 252 | 30 | 60 | 3.0 | 3.0 | 2.4 | 1.2 |

LDL 253 | 45 | 90 | 4.5 | 4.5 | 3.6 | 1.8 |

LDL 301 | 30 | 60 | 3.0 | 3.0 | 2.4 | 1.2 |

LDL 302 | 60 | 120 | 6.0 | 6.0 | 4.8 | 2.4 |

LDL 303 | 90 | 180 | 9.0 | 9.0 | 7.2 | 3.6 |

LDL 304 | 120 | 240 | 12.0 | 12.0 | 9.6 | 4.8 |

LDL 351 | 50 | 100 | 5 | 5 | 4 | 2 |

LDL 352 | 100 | 200 | 10 | 10 | 8 | 4 |

LDL 353 | 150 | 300 | 15 | 15 | 12 | 6 |

LDL 354 | 200 | 400 | 20 | 20 | 16 | 8 |

LDL 401 | 80 | 160 | 8 | 8 | 6.4 | 3.2 |

LDL 402 | 160 | 320 | 16 | 16 | 12.8 | 6.4 |

LDL 403 | 240 | 480 | 24 | 24 | 19.2 | 9.6 |

LDL 404 | 320 | 640 | 32 | 32 | 25.6 | 12.8 |

Main Specification & Weight

Model | Screw Size (DN*L)MM | Machine Dimension (L*W* H) MM | N.W.(kg) | G.W.(kg) |

LDL131 | 130*1180 | 1870*730*1170 | 250 | 395 |

LDL132 | 130*1180 | 2000*960*1230 | 350 | 595 |

LDL251 | 250*1760 | 2690*880*1600 | 500 | 805 |

LDL252 | 250*1760 | 2810*1120*1600 | 800 | 1320 |

LDL253 | 250*1760 | 2810*1360*1600 | 1100 | 1820 |

LDL301 | 300*2220 | 3310*1000*1700 | 750 | 1275 |

LDL302 | 300*2220 | 3500*1300*1700 | 1340 | 2225 |

LDL303 | 300*2220 | 3700*1650*1700 | 1750 | 3030 |

LDL304 | 300*2220 | 4000*2050*1750 | 2150 | 4150 |

LDL351 | 350*2480 | 3610*1100*1850 | 1150 | 1915 |

LDL352 | 350*2480 | 3820*1490*1850 | 1950 | 3205 |

LDL353 | 350*2480 | 4120*1770*1850 | 2800 | 4830 |

LDL354 | 350*2480 | 4320*2290*1850 | 3700 | 6515 |

LDL401 | 400*3100 | 4550*1180*2250 | 2050 | 3245 |

LDL402 | 400*3100 | 4870*1710*2250 | 3850 | 6645 |

LDL403 | 400*3100 | 4790*2550*2250 | 5400 | 9710 |

LDL404 | 400*3100 | 4840*3140*2250 | 7000 | 12960 |

Dehydrator Running Condition

Model | Main Reducer Power (KW) | Mixer Reducer Power (KW) | Total Power | Flush Water Volume | Flush Water Pressure | Maintenance Time |

LDL131 | 0.18*1 | 0.18*1 | 0.36 | 43 L/h |

>2kg/cm2

|

10Min/Day |

LDL132 | 0.18*2 | 0.18*1 | 0.54 | 86 L/h | ||

LDL251 | 0.55*1 | 0.37*1 | 0.92 | 58 L/h | ||

LDL252 | 0.55*3 | 0.37*1 | 1.47 | 116 L/h | ||

LDL253 | 0.55*3 | 0.37*1 | 2.20 | 174 L/h | ||

LDL301 | 0.75*1 | 0.55*1 | 1.30 | 93 L/h | ||

LDL302 | 0.75*2 | 0.55*1 | 2.05 | 186 L/h | ||

LDL303 | 0.75*3 | 0.75*1 | 3.00 | 279 L/h | ||

LDL304 | 0.75*4 | 0.75*1 | 3.75 | 372 L/h | ||

LDL351 | 1.10*1 | 0.75*1 | 1.85 | 126 L/h | ||

LDL352 | 1.10*2 | 0.75*1 | 2.95 | 252 L/h | ||

LDL353 | 1.10*3 | 1.10*1 | 4.40 | 378 L/h | ||

LDL354 | 1.10*4 | 1.50*1 | 5.90 | 904 L/h | ||

LDL401 | 1.50*1 | 1.50*1 | 3.0 | 115 L/h | ||

LDL402 | 1.50*2 | 1.50*1 | 4.5 | 230 L/h | ||

LDL403 | 1.50*3 | 1.50*2 | 7.5 | 345 L/h | ||

LDL404 | 1.50*4 | 1.50*2 | 9.0 | 460 L/h |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.