Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 10 sets per month

:

:

:

:

:

:

:

:

:

:

:

:

:

Perforated Rotatory Grille

Perforated Mesh Screen Definition

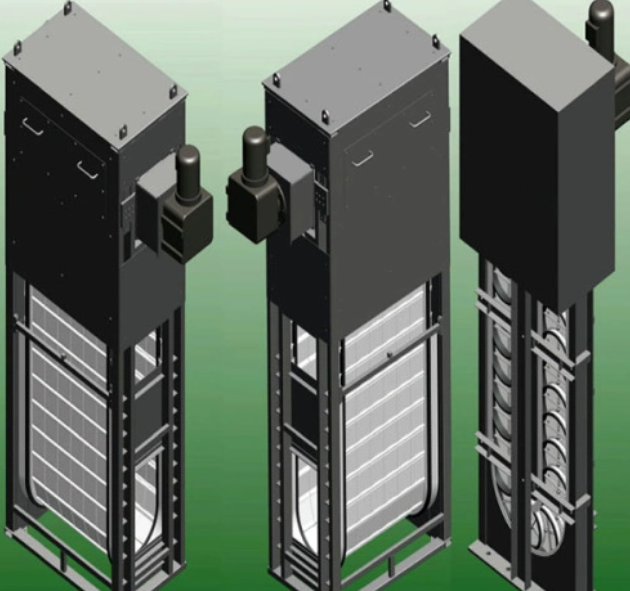

A Rotary Perforated Plate Grille is a Continuous Solid Liquid Separation Equipment for Waste Water Treatment , It Includes a Inclined Frame-Style Rack , a Stepped Rotary System Mounted On a Frame-Type Rack, a Brushing Device, a Flushing Device.The Stepped Slewing System Is Composed Of Lower Rack Reel, Reducer Installed Between Rack Upper Part And Main Shaft Sprocket ,And The Middle Chain Reel Device Which Is Composed Of Interconnected Bending-Formed Trapezoidal Parts.

The Rack Upper Also Configure Another Reducer Gathering With Rotatory Brush.

This Machine Have Solved The The Easy Clogging Problem During The Static And Swimming Grille Reel Interactive Operation,When The Stepped Perforated Reel Collecting The Dirt In The Water Under Rotation Movement, It Also Make Itself And Brush Remain Clean Status To Extend The Grille Life With Simple Structure, Clean Appearance.

Feature & Characteristic

-Step Perforated Mesh Plate Design

-Heavy Duty Stainless Steel Drag Chain

-Adjustable Efficient Cleaning Brush Device

-No Underwater Bearings, Maintenance-Free

-Large Filtration Area to Stop Solid

-Dual Anti-Brush Device

-Lower 300mm Water Head Loss with Large Water Flow Volume

-2-6mm Perforated Plate Make Sure Large Solid Grain

-Easy Mounting no Need Change Civil Condition

-Grille Slag is Very Easy to Clean

-No Screen Slag Turn Over

-Effectively Remove Flat Solid, Fibers,Hairs,

-Easy Operation and Stable Running

-Full Auto Control

Applicant

-Updating of Sewage Treatment Plant

-Top Water Purification

-Power Plant

-Food

-Paper Mill

-Leather

-Textile

-Slaughter House

-Pharmacy

Specification

Model | Flow (M3/D) | Water depth (m) | Channel Depth* Width (m) | Back Wash Water (L/Min) | Motor (kw) |

LPS800 | 30000 | 1.2 | 1.7*1.6 | 174 | 0.75 |

LPS800 | 40000 | 1.5 | 2.0*1.6 | 174 | 1.1 |

LPS1200 | 60000 | 1.5 | 2.0*1.6 | 250 | 1.5 |

LPS1200 | 70000 | 1.8 | 2.3*1.6 | 250 | .1.5 |

LPS1600 | 110000 | 2.0 | 2.5*2.3 | 328 | 2.2 |

LPS1600 | 130000 | 2.3 | 2.8*2.3 | 328 | 2.2 |

LPS1600 | 145000 | 2.5 | 3.0*2.3 | 328 | 2.2 |

LPS2000 | 170000 | 2.3 | 2.8*3.0 | 405 | 3.0 |

LPS2000 | 185000 | 2.5 | 3.0*3.0 | 405 | 3.0 |

LPS2400 | 222000 | 2.5 | 3.5*3.0 | 501 | 3.0 |

LPS2400 | 266000 | 3.0 | 3.0*4.0 | 501 | 3.0 |

LPS2800 | 310000 | 3.0 | 3.5*4.0 | 579 | 4.0 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.