Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 150 sets per month

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Factory Sell Maintenance-free LBSF-10 Continuous Backwash Filter

Automated mechanical filter Helps Grit Water Purifier Performance Feature and Performance

1. Backwash Automatically Without backwash pump, Blower ,Valve ,Bottom

Spraying Nozzle and Collecting and storage tank

2. High Filtrate Rates In a Small Footprint.

3. No moving parts and simple, effective operation.

4. Saves Energy And Running or Maintenance Costs.

5. Produces an Uninterrupted Treated Water Stream, With a Minimal

Resultant Waste Stream For Disposal Or Further Treatment.

6. High Efficient, 24 Hours Of Continuous Operation, No Need Stop To

Backwash.

Overview

LBSF model Continuous Backwash Filter is an up-flow, moving bed filter that is constructed with various media depths for different applications and configurations.

It is a set of flocculation, clarification, filtration as one of the continuous operation of the sand filter .representing the highest level of continuous filtration technology. Through the built-in flushing system continuous flushing, because there is no need to stop recoil,its operation and maintenance is very easier. It is widely used in drinking water, industrial water, sewage deep treatment and center water re-circled treatment

How it Work

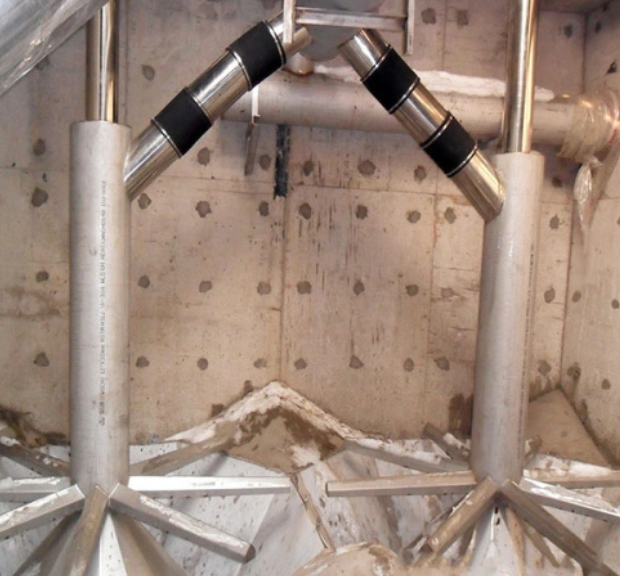

Raw water enters near the bottom of the tank by means of a stainless steel water distributor. Suspended solids are filtered out as the raw water flows up through the media bed. As the filtrate reaches the top of the filter, it passes over the effluent weir and is discharged. A portion of the filtrate is diverted through the sand washer and used for cleaning and transferring the waste solids.

The filter employs a backwash rinse that is performed continually while the tank is processing water. An air lift pump, located at the center of the module, draws the media from the bottom of the filter up into the wash box. As the media is released into the wash box, it falls into the sand scrubber where the filtered solids are separated from the sand. From there, the filtrate carries the solids out as waste (backwash). The washed sand falls down onto the media bed for continued use.

Applications

It can be Applied In Both Municipal Wastewater And Industrial Water Treatment Processes.Whether you need reuse quality water, nutrient removal, industrial water treatment, or raw water treatment, Loren 's sand filter delivers unmatched effluent quality, meeting the highest of environmental standards.

A. Municipal

-Suspended Solids Reduction

-Water Reuse

-Denitrification and Nitrification

-Chemical Phosphorus Removal

-Pretreatment to Other Process

B. Industrial

-Metal Finishing

-Backwash Recovery

-Process Water

-Cooling Tower Blow Down

-Steel Mill Scale

-Chemical Processing

-Ideal For Pretreament In Lieu Of Gravity Filters

Specification and Model Selection

Model | Capacity (M3) | Filter Area (M2) | Dimension DN* Height(mm) | Air Volume (L/Min) |

LBSF-10 | 6-10 | 1.0 | ¢1150*4840 | 50 |

LBSF-15 | 9-15 | 1.5 | ¢1400*5090 | 70 |

LBSF-20 | 12-20 | 2.0 | ¢1600*5500 | 100 |

LBSF-30 | 18-30 | 3.0 | ¢2000*5900 | 120 |

LBSF-40 | 24-40 | 4.0 | ¢2260*6260 | 150 |

LBSF-55 | 33-55 | 5.5 | ¢2650*6610 | 180 |

Comparison to Traditional Mechanical Filter

Item | Continuous Sand Filter | Traditional Sand Filter |

Type | continuous | Lowe Flow Pressure |

Efficiency | Stable | Change as per period of filter and backwash |

Head lost | Small with Stable | Big Change as per period of filter and backwash |

Middle water tank | None | Need |

Re-flux Pump | None | Need |

Filer process | Continuous | Sequence run with stop machine for back washing |

Control device | None | Complex with each process set one auto valve and press gauge |

Operation | Simple | Complex |

Waste water Adaptability | Good | Limited due to backwash SS on its filter layer |

Backwash process | Constant | With abnormal overload under huge backwash water volume |

Flush Effect | Thorough with no angle | May with parts no flushing |

Maintenance charge | Extremely little | Bigger work |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.