Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

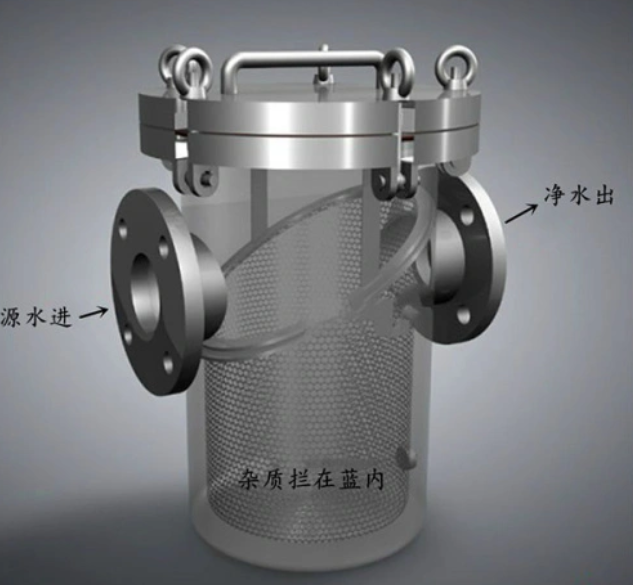

LBS Series Hair Separator

Basket Filter Definition

Basket Filter is Used On Oil Or Other Liquid Pipelines To Filter Debris In The Pipeline To Protect The Normal Work Of Air Compressor, Water Pump, Meters And Instruments Etc.

Vertical Straight-Through Decontamination Device Applicant Range

-Swimming Pool Pipeline with Fresh Water Pump

-Petrolatum

-Chemistry

-Pharmacy

-Food Processing

-Environment Protection

Feature

- About 2-3 times Large filter Area than Y or T shape Filter

-SS304 Mesh with Hole DN 3-6

-Optional Choice of Gauge

-Pressure lost Small due to large Flow Volume

Suitable Filtering Material

-Weakly Corrosive Materials in Petrochemical Production

A. Water

B. Nitrogen

C. Oil Product

D. Hydrocarbons

-Corrosive Materials For Chemical Production

A. Caustic Soda

B. Soda Ash

C. Concentrated Dilute Sulfuric Acid

D. Carbonic Acid

E. Acetic Acid,

F. Ester Acid

-Low Temperature Materials In Refrigeration

A. Liquid Methane

B. Liquid Ammonia

C. Liquid Oxygen

D. Various Refrigerants

-Materials For Hygienic Requirements In Light Industry and Pharmacy

A. Beer

B. Beverage

C. Dairy Products

D. Grain Slurry

E. Medical Supplies Etc.

Parameter Data & Model Selection

Model | Cylinder DN* Thick (mm) | Over All High (3mm) | Basket DN(mm) | Accuracy (µm) | In & Out Flange (mm) |

LBS-133 | 133*3 | 300 | 100 | 60-400 | ¢40/50 |

LBS-159 | 159*3 | 360-400 | 120 | 60-400 | ¢65/80 |

LBS-219 | 219*3 | 470-550 | 180 | 60-400 | ¢100/125 |

LBS-300 | 300*3 | 650-730 | 238 | 60-400 | ¢100/150 |

LBS-400 | 400*3 | 630-780 | 360 | 60-400 | ¢150/200 |

LBS-500 | 500*3 | 930-1200 | 460 | 60-400 | ¢250/300 |

LBS-600 | 600*3 | 1375-1775 | 500 | 60-400 | ¢250/300 |

LBS-800 | 800*4 | 1625-2025 | 700 | 60-400 | ¢300/400 |

Function Requirement

- Must Set a Air Drainage Valve On its Top Cover with Inspection hole

-Design Pressure≥1.5 times Working Pressure

-Test Pressure≥1.5 times Design Pressure for 30 Minutes keeping

- Total Holes Area ≥2.0 times Pipe Cross-Sectional Area

-Working Temperature:-80℃—+450℃

-Nominated Diameter: DN15-DN600

-Nominated Pressure:PN1.0—5.0Mpa

-Sealing Material: PTFE, Nitrile Rubber, Oil-Resistant Asbestos Glue

Design Criteria

-"Code for Design of Sports Buildings" JGJ31-2003 JGJ265-2003

-"Code for Water Supply and Drainage Design of Swimming Pools and Aquatic Amusement Pools" CECS14: 2002

-"Code for Design of Building Water Supply and Drainage" GB50015-2003

-04S107 "Swimming Pool Accessories Installation And Equipment Selection"

Maintenance

-Especially Protect its filtrate or core (SS Mesh &Frame)

-Regularly Clean the Debris in The core after a period Running

-During Tiding Core, Pay More Attention to The Mesh no Deforming or Damage, Otherwise , Can Not Get Good Filtration Results Thus To Damage Compressor, Pumps And Instruments.

-Change the damage Stainless Steel Mesh if Deformed Or Damaged

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.