Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 50 Sets Per Three Months

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

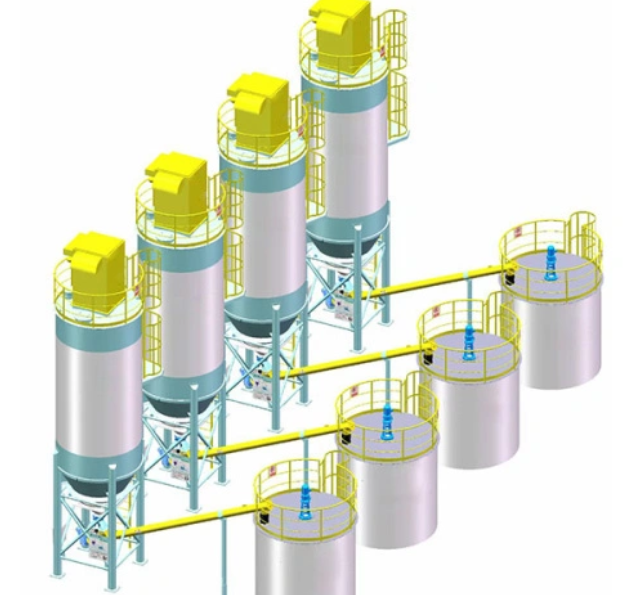

Lime Silo Dosing System

Definition of Automatic Lime Milk Preparation And Dosing System

It Is a Kind Of Cyclone Storage Tank Of Such Bulk Material As Grain, Cement, Fly Ash, Lime Powder etc. With Material Level or Volume Display System on its upside and Supporting Electric Dust Removal Device On its Top Position as well as Screw Pump joint.

Calcium Hydroxide Dosing Silo Composition

-Lime Silo (Including Dust Collector, Material Level Gauge, Arch Breaking And Dehumidifier, Ladder, Fence);

-Vibration Feeding Device

-Quantitative Feeder

-Screw Conveyor

-Balance Water Tank (Liquid Level Control)

-Lime Milk Dissolving Tank

-Liquid Medicine Output Pump (Dosing Pump)

-Pump Body And Pipeline Flushing System

-Electrical Control System

Feature of Fly Ash Powder Storage Tank

-Storage Capacity:10-10000 M3

-Lime Milk Preparation Density Range: 5%-10%

-With Rainproof & moisture-proof function

-Advanced Unloading Oscillator Makes Unloading Smoother

-Continuous Powder Feeder with VF Device Assures High Accuracy

-Advanced Quicklime Digestion Unit Assure High Digestion Efficiency

-Special Lime Pipeline and Valve with No Blocking & No Leakage

-Imported Liquid Level Meter

-Easy Operation

-Prevent lime from Flushing

-Reduce Urban Air Dust Pollution

-Small Footprint

-Long Working Life

-Low Cost

Model Selection and Parameter Data of Soda Ash Silo Dosing System

Model /Volume (M3) | Silo Size DN*Height (m) | Spiral Conveyor ( kg/h) | Dissolving Tank Size DN*Height (m) | Total Power (kw) | Footprint L*W (M) |

LLS-10 | 1.9*8.0 | 1-50 | 1.0*1.3 | 6 | 5.0*3.0 |

LLS-20 | 2.5*8.0 | 5-100 | 1.7*1.5 | 8 | 6.0*3.5 |

LLS-30 | 2.9*8.5 | 10-200 | 2.0*1.8 | 10 | 8.0*4.0 |

LLS-50 | 2.9*11 | 50-500 | 2.4*2.2 | 14 | 10.0*5.0 |

LLS-70 | 4.0*11 | 100-1000 | 2.6*2.5 | 20 | 12.0*6.0 |

LLS-100 | 5.0*11 | 200-1500 | 3.0*3.0 | 25 | 10.0*5.0 |

LLS-150 | 6.0*11 | 200-2000 | 3.0*3.0 | 28 | 13.0*6.0 |

LLS-200 | 6.0*13 | 200-3000 | 3.0*3.0 | 30 | 13.0*8.0 |

LLS-300 | 8.0*13 | 500-5000 | 3.0*3.0 | 30 | 15.0*8.0 |

LLS-500 | 6.0*22.3 | 500-5000 | 3.0*3.0 | 45 | 29.0*6.0 |

Working Principle

The Lime emulsion or dry powder automatic dosing device is to store a certain amount of lime powder (Cao, CaoH) (through negative pressure suction, material transport vehicle blowing, screw conveyor input & manual pouring) in a specially made container (lime In the silo), the dust generated is collected by the bag dust collector, and vibrated by the vibrator to falls back to the powder silo.

The stored lime powder is loosely and evenly fed by the vibrator to the frequency conversion speed regulating feeder for quantitative feeding (dry powder dosing process), the screw conveyor is transported to the lime milk dissolving tank, mechanically stirred to produce emulsion, and the liquid dosing pump will deliver the emulsion with a concentration of 5%-10% to the dosing point of the medicinal solution (emulsion dosing process). The Material Level Is Displayed Through PLC Control Screen; the liquid level is high and low, and the system stops when the liquid level is low, and automatically runs when the liquid level is high; the concentration of the liquid medicine is controlled by the inverter frequency modulation to control the motor speed of the feeder to achieve quantitative feeding.

Main Function of Auto Lime Dosing System

-Fully PLC Control All the System

-All System Equipment Run and Alarm Display

-All Signal Remote Output

-Internet Entry Pot To Realize Host Computer Monitoring

-Auto Feeding Material as per Set Value Density

-Auto Closed Loop Dosing as per Front Source Water Volume and PH

-Auto Closed Loop Dosing as per After Settled Water Volume and PH

Main Applicant

-Grain Storage Like Wheat, Corn & Rice

-Mineral Product Storage Like Raw Material of Coal &Iron

-Large Quantity Crude Oil& Refined Oil Storage

-Store Chemical Product- Soda Ash, Hydrochloric Acid & Vinyl Chloride

-Store Textile Material like Cotton & Woven Yarn

-Store Biomass Energy Like Biomass Pellet Fuel & Straw

-Store Rubber and Wood

-Store Aquatic Products

-Engineering Construction

-Commodity Concrete Mixing Plant

-Road & Bridge Water Conservancy Projects

-Urban Construction Project

-Waterworks Or Municipal Waste Water Disinfection

-Rural Drinking Water Disinfection

-Hospital Waste Water Disinfection

-Swimming Pool Disinfection

-Chemical Waste Water Decolonization and Cod5 Reduction

-Industrial Circulated Water Sterilization, Algae Removal and Sludge Stripping

-Oil Rejection Water Sterilization, Disinfection and Descaling

-Industrial Desulfurization and Denitrification

-Sewage Reuse

-Aquaculture Waste water

-Dyeing and Printing Waste Water

Note

-It Is Strictly Forbidden To Tilt Its Main Body & Deform The Outriggers During Mounting Period .

-Outrigger Bottom Must Be Firmly Welded To Its Foundation Embedded Parts

-Do Wind & Lightning Protection Measure

-It Is Strictly Forbidden To Hit The Outriggers Its Body Strongly

-Regularly Check & Clean The Powder Adhesion Of The Dust Collector Bag

-Its Foundation Must Be Firm And Meets Architectural Design Specifications

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.