Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 100 Sets Per Month

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

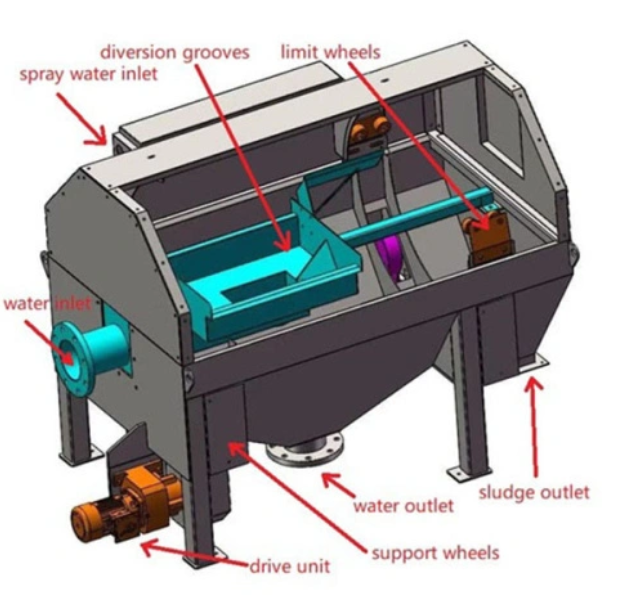

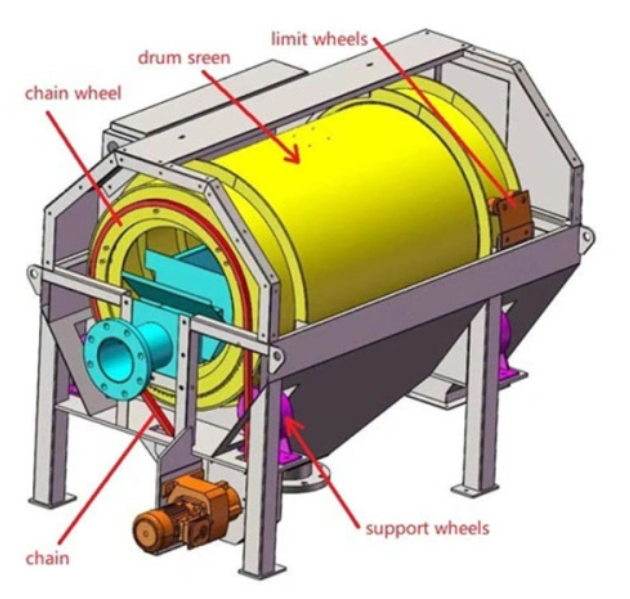

LIDF Series Internal Flow Fine Micro Drum Filter

Concept

Our LIDF Micro Drum Filter Is a Continuous and Effective Fine Screen For Removing Suspended Solids In The Water Under High Efficiency With Simple Structure , Higher Liability , Less Room Occupation Compared To Similar Ones From Other Competitors. We Have Various Grid Gap For Option

Characteristic

-High Interception Rate

-No Block Happen by Adapting Wedge Grid Or Punching Screen Elements

-Large Flow Rate and Reduces Head Loss.

-Corrosion-Resistance SS Material Fit For High Temp& High Density Liquid Filtration.

-Compact Drum Design Make Large Filtering Area and Little Consumption

-Auto or hand control Back-washing Nozzle to Clean Onside Impurities Freely

-Fully Automatic Work without operator supervision

-Fully Closed Design to get rid of secondary pollution

- Easy to maintain and Replace

-Overall SS Structure with Anti-Corrosion Performance

Drum Filter Feature

-SS304/SS316L Integrated Structure

-Internal Spray System

-Sealing Cover Plate

-4-20 RPM Speed Regulation Range

-Automatic Slag Blow

-Time Back Flush

Optional Choice

A.SS316L Integrated Structure

B.Liquid Level Switch

C.Backwash Solenoid Valve

D.Backwash Pump

E.Electric Control Cabinet

Applicant

-MBR Systems Protection

Membrane bioreactors(MBR) using hollow fiber membranes are clogged and damaged by hair and fiber. For their protection every hair and fiber has to be removed from the influent. Screen with a mesh size of 1mm or smaller is required.

-River And Sea Outfalls

Where Biological Treatment Is Not Available, The Mechanical Treatment Should Be As Thorough As Possible. Rsm Screening Removes Up to 60% of Suspended Solids and up to 30% of BOD/COD. Removal Can Be Further Improved By Flocculation To:

-95% of Suspended Solids

-65% of BOD/COD

-60% of Phosphorous

-Process Water

It Permits Reuse Of Effluent As Wash Water Or Process Water.

-Industrial Effluent Pre-Treatment or Product Recovery

A. Pulp And Paper: Removal Or Recovery Of Paper Fibers

B. Meat Processing: Recovery Of Scraps

C. Agriculture: Separation of Fruit Residues And Peels

D. Breweries: Pre-treatment of All Effluents

E. Laundries: Removal of Fibers

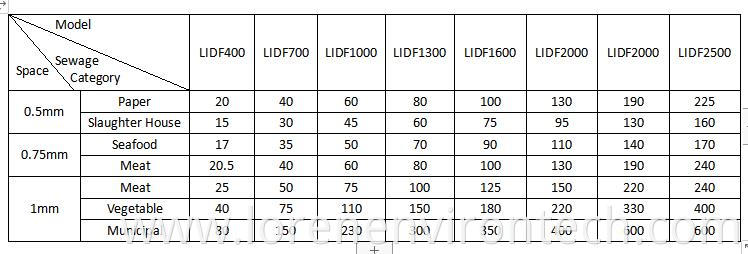

Model Selection Reference

Flow Vlume of Space Slectdion

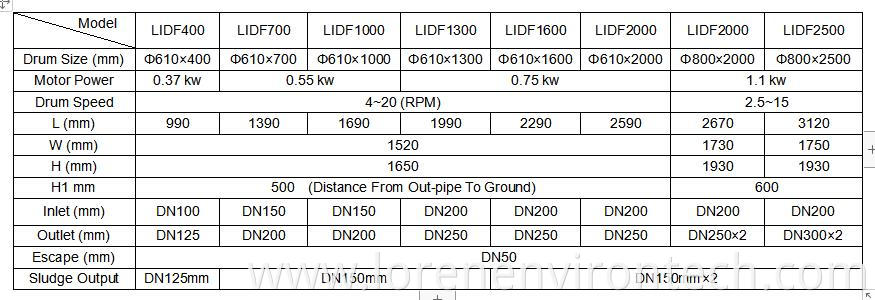

Detail Specification for Reference

Working Principle

The Drum Is Horizontally Supported By Four Wheels, and Is Driven By TEFC Reducer, Anti-Corrosion Roller Chain and Stainless-Steel Sprocket. The Spray System Automatically Sprays Clean Water. Its Integrated Design, Sturdy Construction,& High-Quality Stainless-Steel Materials Ensure That The Equipment Can Run For Long Periods Of Time With Low Energy Consumption Without Trouble,and Is Easy To Maintain. The Overflow Trough Extends To The Inside Of The Drum, and Raw Water Flows In From The Overflow Trough, and Is Evenly Injected Into The Inner Wall Of The Drum Through The Distribution Of The Weir. The Filtered Raw Water Is Guided To The Central Drainage Area Through The Floor Deflector and Flows Into The Next Sewage Treatment Unit; The Slag In The Raw Water Is Blocked On The Inner Surface Of The Drum Filter,and Is Discharged Through The Inner Wall As The Drum Rotates The Slag Is Conveyed Spirally To The Tail Slag Hopper. As The Drum Head Rotates, The Entire Screen Surface Can Be Continuously Or Intermittently Sprayed By An Internal Spray System.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.