Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 10 Sets Per Month

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

20 mm Particle Sewage Rotary Belt Filter

Sewage Filtration Equipment

1. Breakthrough & Definition

Loren Special Rotating Belt Filter is An Idea TSS Over 20000ppm Physic Sewage Filters which Achieves An Integrated Rapid Separation Equipment For Mud, Sand, And Grease By Utilizing Our Independently Developed High-Efficiency Filtration And Separation Technology

The Rotating Belt Separator Breaks Through The Traditional Basic Principles Of Mud Removal, Slag Removal, Sand Removal, And Grease Removal Through Gravity, Center Force, Buoyancy Etc.

The difference between Rotating Belt Filter and Filter Cloth Filtration lies in the different filter pore size;

Rotating Belt Filter Pore Zize /microsieve:y 200~400μm,

Rotating depth Cloth or Elastic Material Filter Pore Zize: ≤ 10μm.

Loren Special Belt Filter Adjustable Speed: 144~240m/h.

2. Structure and Working Principle

Structure

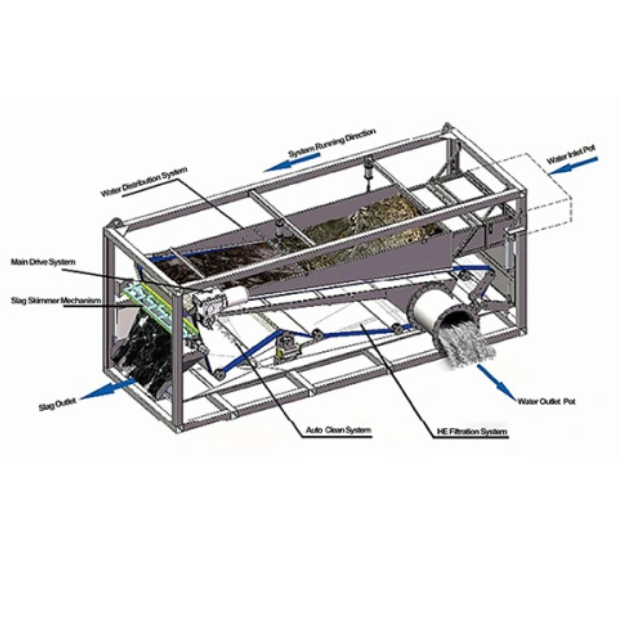

The Rotating Belt Separator is Mainly Composed Of a Driving Device, a Transmission System, a High-Efficiency Filtration System, And a White Dynamic Flushing System, a Water Distribution Mechanism, a Drainage Mechanism, a Control System Etc.

Working Principle

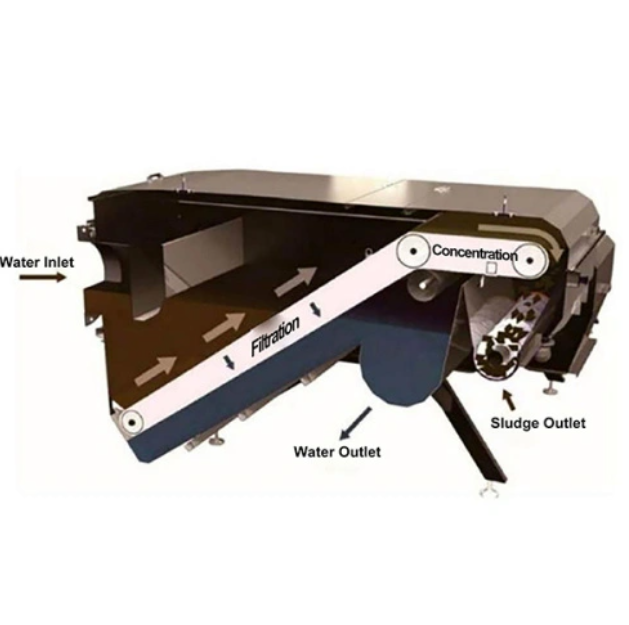

During Operation, The Sewage Enters The High-Efficiency Filtration System Through The Water Distribution Mechanism. The Sludge, Sand, Grease, Etc. In The Sewage Are Trapped On The High-Efficiency Filtration System. The Trapped Sludge, Sand, Grease, Etc. Are Transported To The Collection Barrel Or Screw Press Through The Slag Discharge Mechanism. Dehydrated Inside Before Being Shipped Out.

3. Applicant

A. It Is Suitable For Large-Volume Sewage Treatment Plants As First-Level

of Effeluent Filtration Machine

B. It Can Replace The Primary Or The Back-End Sedimentation Tank.

C. Esp. For Current European and USA High SS of Toilet or STP Site

D. For Industrial Wastewater which Contains High Slag Sand and Hair Etc.

4. Rotary Belt Filter Features and Characteristics

A. Fast Separation efficiency under 5 Seconds

for such as hair, fiber, sludge and sand in raw sewage

B. High Accurancy

1) 95% Large Size Impurities Removal Ratio.

2) 30%-60% Suspend Solid Disposal Ratio.

3) 20%-65% Organic Matter (Difficult To Degrade) Disposal Ratio.

4) About 3% To 8% Trapped Sludge Fit for Direct Dewatering

C.Low Energy Consumption

Electricity Consumption Per Ton of Water Is 0.01-0.03kw/h.

D.Taken Up Area: 1/10 of Primary Settler esp. For Underground STP

E. Simple Maintenance: 2 Workers Change Mesh In 15 Minutes

F. Strong Impact-Resistance Adaptability and Stable Outlet Water Quality In Various Complex Situations

G. Intelligent Auto Control System

with one Key Stop and Start and Remote Supervison Function as well as Auto Stop After Alarm For Fault

H. Long Service Life: Over 20 Years

I. Investment Cost : 30%-60% Lower of that from Primary Settler

J.Trapped Sludge can Directly Concentration or Through Screw Press to get 80% moisture Dry Sludge

5. Successful Performance Site

Our Rotary Belt Filters have been used in

-Tiendeholmen wastewater treatment plants,

-Breivika Primary Treatment of STP

-Bangsund STP

-Nedre Romerike STP

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.