Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 200 Sets Per Month

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Factory Sell Maintenance-free Rotary /Float Decanter For SBR CAST Pool, ETP, WWTP

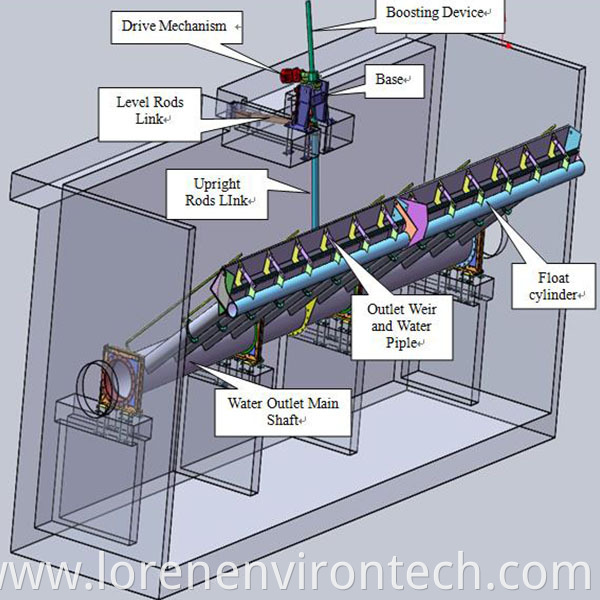

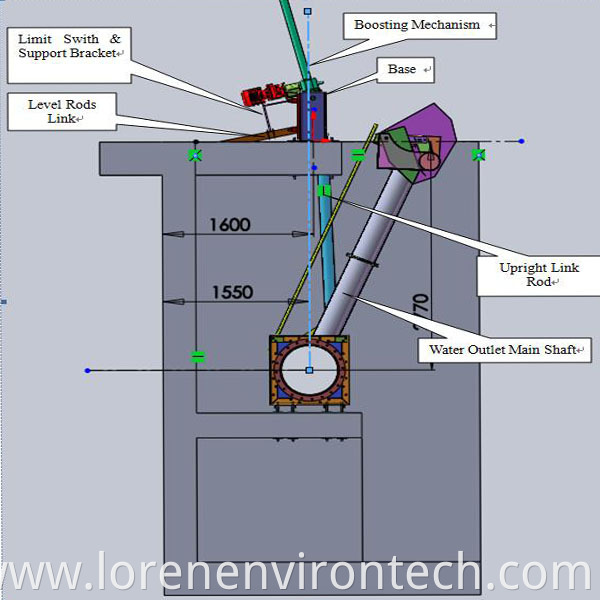

Composition & Working Principle

Working Principle

The Rotary Decanter Is Mounted On The Pool Inside Bracket Base with Supporting Bearings. The Electric Push Rod Deceleration Device Is Installed On the Support above the Inside Pool. The electric push rod drives the decanting mechanism to rotate and swing around the center of the lower support. During The Aeration And Sedimentation Stage, The Decanting Weir Is Located Above The Water Surface. when decanting, the decanting weir is lowered to below the water surface by the control system for drainage. When the decanting is completed, the decanter quickly returns to the initial state. The decanting process is carried out as per the preset procedure. The water flow into the decanting weir is in a laminar flow state. The descending speed of the decanter keeps the water output stable.

Composition

The decanter is mainly composed of Electric Reducer, Electric Push Rod, Water Collection Tank, Buoy, Water Collection Pipe, Electric Control Cabinet and Other Parts.

Automated Decanter Helps Sequence Batch Reactor Performance Feature & Performance

-Decanter and Outlet Pipe connected flexibly

-Decanter Hole Layout under Its Surface Averagely

-Automatic Closing Mechanism Based On Gravitation and Flow.

-Designed without Conventional Valves And Pumps.

-No Sludge Layer Disturbance from Decanter Pipe Due To Max. Distance By

Vertical Free Movement

-Low Power Consumption with Motor Power between 0.37kw and 1.5 KW

-Running Stably and Maintaining Easily

-Auto Center, Remote Control and Field Manual Control

-Automatic Speed Change and Return (2-3 times)

-Low Operating Cost.

-Compact Structure, Simple Operation

Applicant

Filtering The Upper Clean Filtrate of SBR/CAST Reactor Tank

Main Decanter Technical Parameter Data

Model | Flow(m³/h) | Decanter Depth(m) | Outlet Weir length(m) | Outlet Pipe DN (mm) | Drive Power(kw) |

LSD100 | 100 | 1~3 | 1 | 200 | 0.37 |

LSD200 | 200 | 1~3 | 2 | 300 | 0.37 |

LSD300 | 300 | 1~3 | 2.7 | 350 | 0.37 |

LSD400 | 400 | 1~3 | 3.5 | 400 | 0.37 |

LSD500 | 500 | 1~3 | 4.2 | 500 | 0.37 |

LSD600 | 600 | 1~3 | 5.2 | 500 | 0.55 |

LSD700 | 700 | 1~3 | 6 | 600 | 0.55 |

LSD800 | 800 | 1~3 | 7 | 600 | 0.55 |

LSD1000 | 1000 | 1~4.5 | 8.2 | 600 | 1.1 |

LSD1250 | 1250 | 1~4.5 | 10 | 700 | 1.1 |

LSD1500 | 1500 | 1~4.5 | 12 | 600*2 | 1.1 |

LSD1750 | 1750 | 1~4.5 | 14.5 | 600*2 | 1.1 |

LSD2000 | 2000 | 1~4.5 | 16 | 700*2 | 1.1 |

LSD2500 | 2500 | 1~4.5 | 20 | 700*2 | 1.1 |

LSD3000 | 3000 | 1~4.5 | 24 | 800*2 | 1.5 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.