Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 20 Sets per three months

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

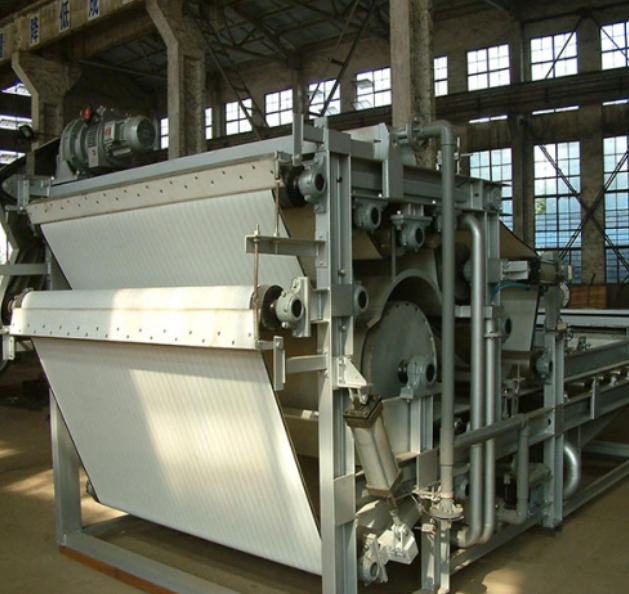

LBP Series Belt Press Filter

Loren Continuous Cloth Tension Filter Press Definition

It Is Mainly Used For Processing The Sludge Which Is Not Concentrated( Water Moisture99.2-99.6%) In The Thickening Pool, Such As A/O Or SBR Residual Sludge With Both Concentrating & Dewatering Functions. Higher Capacity Sludge Is Thickened By The Gravity by Fixing Frame on Foundation with Anchor to fit for Harsh Working Environment With The High Temperature& 100% Humidity. It Can Also Work as a Sludge ( With Water moisture 95-98%) thickener or Concentrator Finally To Yield Out Sludge Cake and Separating Liquid After Digestion and Absorption Of Advanced Foreign Technology

Industrial Belt Type Filter Juicer

It also has energy-saving, high degree of automation, automatic access to materials, continuous work, versatility, full pressure. filtration, the filter cake moisture content is low, easy operation and maintenance, etc., is a higher juice squeezed juice equipment.

Use of such a juicing equipment management can make juice out of the juice rate by 20-35%, juice rate is as high as 70-80%(depending on the raw material), can greatly reduce the production cost, improve the economic efficiency of enterprises

This equipment can also be used in food, chemical industry, environmental protection, light industry and so on some of the powder and paste objects of pressure filtration dehydration.

Loren Belt Filter Press Feature & Merit

-High Efficiency & Large Processing Capacity

-Low Energy Consumption & Low Operating Cost

-Low Sludge Moisture & Less Chemical Consumption

-Simple Structure

-Easy Maintenance & Management

-No Vibration & No Noise

-Smooth and Reliable Continuous Working Automatically

-Adopts Pipeline Filters Save Tap Water & Reduce Run Cost

-Effective Belt Width Increases By 150 mm

-Strengthen Initial Pressure Roller Press Force Distribution Design

-Auto Cylinder Deviation Correction System Prevents Filter Cloth Deviation.

-Automatic Control & Continuous Working

- Economical , Reliable & Wide Application.

- Advanced Concentration Device To Flocculate Slurry Preferably

- Pneumatic Regulated Adjustable Belt Ensure its Stability

-Multi-Point Safety Detection&Emergency Stop Device Improve Performance

-Humanized Design With Auto Deviation Correction Air Chamber Device

-Drum Thickener or Belt Thickener or others optional as per different concentration

-Clog-Free Performance: Fit for Sludge with oil, Grease and Fiber Perfectly

-Stainless Steel Module Structure Make It Run In A Long Life Time

Fully Enclosed Gravity Belt Filter Press Working Principle

The Wastewater Is Pushed Into The Spiral Dehydrator,The Sludge Will Bear Heavier Pressure Of The Helical Aixs Blades And Began To Carry On Dewatering After Continuously Being Moved To The Outlet Port Of The Sludge Cake Due To The Gap Among The Helical Blades Gradually Becoming Narrower And The Water Will Then Comes Out From The Gap Between Fixed Plates And Moving Plates.

Belt Filter Press For Sludge Thickener Applicant

-Manufacturing Plant

-Food & Beverage Factory

-Farms & Agriculture

-Construction works

-Energy & Mining

-Sewage Treatment Plant

-Hotels & Restaurant

-Garment Shops

-Building Material Shops

-Machinery Repair Shops

-Home Use

-Retail

-Printing Shops,

-Urban Life Sewage

-Textile Printing & Dyeing

-Electroplating

-Paper Making

-Iron Mining Tailing or Metallurgy

-Leather Industry

-Brewing

-Coal Washing

-Petrochemical

-Chemical

-Pharmaceutical

-Ceramics,

-Livestock Products Industry,

- Aquatic Product Industry

-Water Clarification Plant Sludge Dewatering or Concentration

-Butchery & Husbandry.

-Ethanol Residue

-Slaughter Industry

-Car Wash Factories

Main Technique Parameter & Model Selection

Model | Capacity (M3/h) Under Inlet SS (0.5-1.5%) | Dry Sludge (kg/h) | Total Power (KW) | Dimension L*W*H (MM) | Weight (KG) |

LBP-500 | 2-3.3 | 30-50 | 0.75 | 2150*1050*2350 | 660 |

LBP-750 | 3-5 | 45-75 | 0.75 | 2300*1300*2350 | 880 |

LBP-1000 | 4-7 | 63-105 | 0.75 | 2350*1550*2350 | 960 |

LBP-1250 | 5.5-9.5 | 83-143 | 0.95 | 2350*1800*2400 | 1220 |

LBP-1500 | 9.5-15.5 | 143-233 | 1.50 | 2900*2130*2500 | 1800 |

LBP-2000 | 13.5-22.5 | 203-338 | 1.85 | 2900*2630*2500 | 2200 |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.