Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 10 Sets per month

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

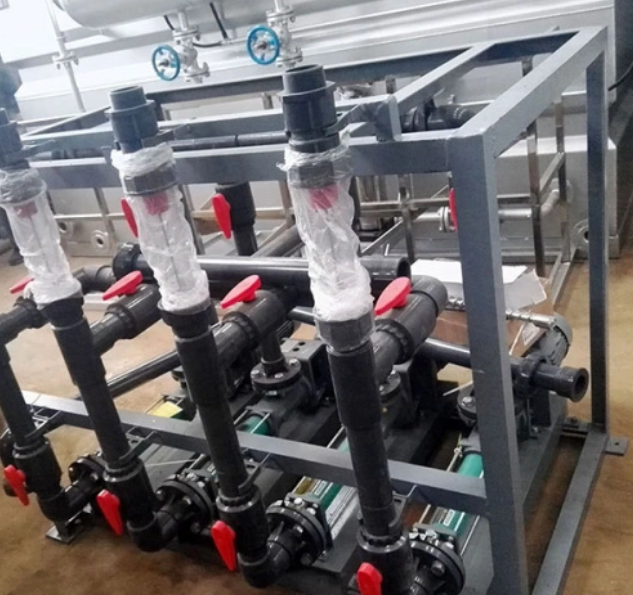

Polymer Preparation & Dosing Unit

Affordable Chemical Dosing Machine Definition

This Auto Chemical Feeding Machine Integrated Three Slots Together to Realize Process of Dilution , Mixing Homogenization, Maturation and Storage Under Function of Supporting Agitators,Auto Feeding Motors thus to Achieve preparing and adding PAM agent continuously. Its Raw Material Can Be Powder Or Liquid. It Can reduce the occurrence of particles (block); dry powder and water inlet as well as the liquid density can be adjustable as per specific requirement

Mining Slurry Treatment Dosing Device Component

It Consists Of Bunker, Dosing Unit, Infiltration Device, Chemical Dissolving Unit, Maturing Device, Chemical Storage Device, Agitator, Level Control System And Electric Control. Vacuum Conveyor, Online Dilution System And Chemical Dosing System Can Be Selected As Accessories.

Waste Water Chlorine Dosing Equipment Working Principle

Dosing Screw Conveyor Is Driven By Electron Motor With a Gear Unit. The Rate Size Of Powdered Flocculant Is Controlled By Timing Control Of The Screw Operation. The System With The Flocculant Dosing Pump Can Be Delivered In Required Suitable Kind Of Material According To The Customer’s Requests.

Automatic Polymer Dosing System Features

-High Dosing Accuracy

-Completely Automatic Running

-Optional Powdered Or Liquid Feed Design To Meet Different Requirement

-Integral Dosing Head Deaeration.

-Easy For Installation, Operation& Maintenance.

-High Operational Reliability.

-Easy Operation With Three Slot Continuous Preparation.

-Precision Design To Prevent Particle Blocking

-Free Adjustment Of Dry Powder , Water Inlet And Concentration Needed

-Ensure That The Curing Time Of The Liquid Is From 45 To 60 Minutes

-e-Control Cabinet With Proportion Liquid Solution Melting Controlling.

-Its Alarm Signals Alert Adding Under Lower Chemical Level In The Hopper.

-Optional: Liquid Polymer Feed Function

-Optional: Vacuum Feeder

-Optional: Online Dilution System / Static Mixer

-Tank material optional:epoxy CS/ SS304 or SS316L, PP, HDPE

-Accessories In Great Variety.

(All Customized Models Are Available By Online Inquiry).

Main Technical Parameter & Model Selection

Model | Capacity ( (L/h) | Power (KW) | Dimension (mm) | Net Weight ( kg) | Inlet/Outlet Flange mm) |

LPT200 | 200 | 0.54 | 940*520*1450 | 200 | DN25 |

LPT500 | 500 | 1.20 | 1370*948*1490 | 320 | DN25 |

LPT1000 | 1000 | 2.70 | 2077*1382*1769 | 500 | DN32 |

LPT1500 | 1500 | 2.43 | 2130*1387*1808 | 540 | DN32 |

LPT2000 | 2000 | 1.78 | 2200*1550*1969 | 640 | DN32 |

LPT2500 | 2500 | 2.48 | 2400*1270*2000 | 790 | DN40 |

LPT3000 | 3000 | 2.48 | 2400*1550*2300 | 810 | DN40 |

LPT4000 | 4000 | 3.35 | 2700*1600*2200 | 950 | DN40 |

LPT5000 | 5000 | 4.75 | 2850*1500*1750 | 1000 | DN50 |

LPT6000 | 6000 | 4.75 | 3800*1500*2250 | 1150 | DN50 |

LPT7000 | 7000 | 4.80 | 3850*2000*2200 | 1200 | DN50 |

LPT8000 | 8000 | 4.80 | 4580*1600*2350 | 1250 | DN60 |

LPT10000 | 10000 | 6.40 | 4000*2040*2650 | 1450 | DN60 |

Note:

-The PAM Mature or Aging Time is 60 Minutes

-Dosing Volume Should Be Tested Under Specified Different Condition,

-Normally Adopts SS304 Structure for the Tank & Agitator

-Pipe System Material: UPVC

-Special Requirement like Ex-Proof , Source us Specifically

Applicant

This Three-Chamber Automatic Chemical Coagulant Powder Dosing System Can Be Widely Applied In The Following Fields

-Sludge Dewatering or Reduction

-Solid Management

-Chemical Industry

-Mining Tailing

-Pulp Thickening

-Dosing Coagulant

-Filter Aids

-Disinfection & Acid-Base Fluid For Water Treatment.

-Scale Inhibitor Dosing Agentia In Cooling Or Circulating Water,

-Printing & Dyeing Industry.

-Hotels

-Manufacturing Plant

-Food & Beverage Factory

-Pharmacy

-Paper Mill

-Food And Beverage

-Municipal Sewage Treatment & STP

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.