Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

66Product Categories

Send Inquiry

Payment Type: T/T

Supply Ability: 2000 pcs per month

:

:

:

:

:

:

:

:

:

:

:

:

:

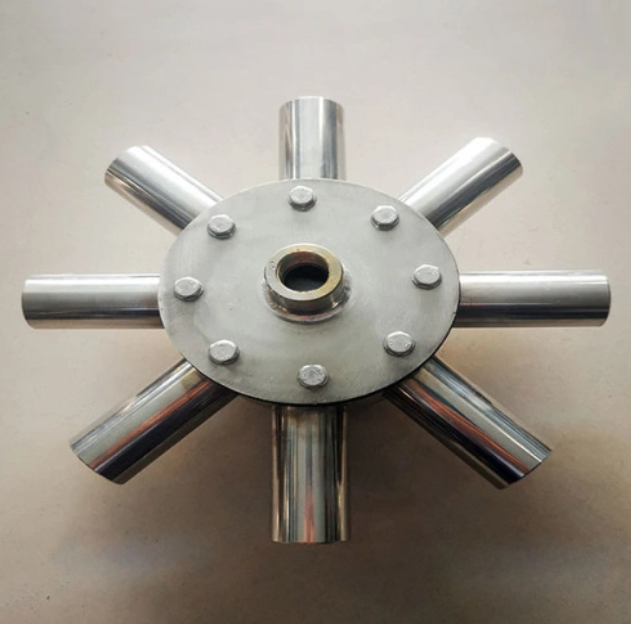

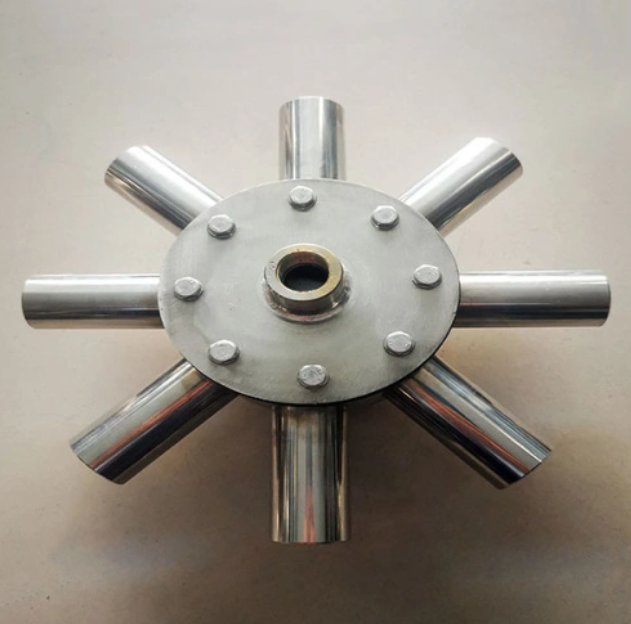

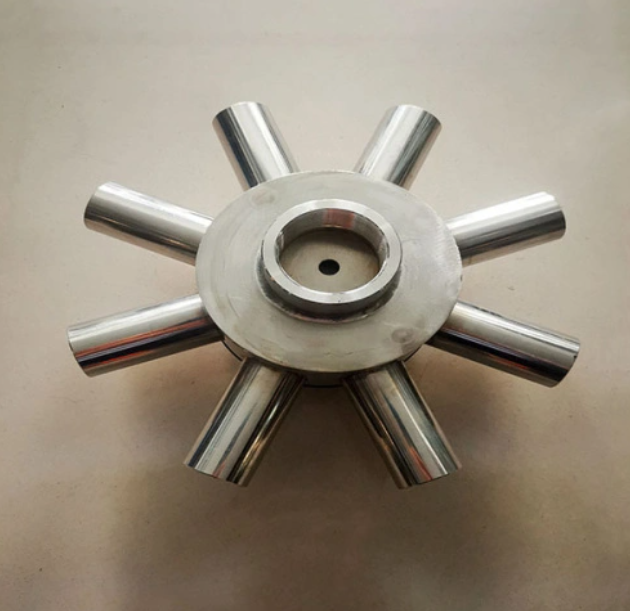

Loren LTJ Series Dissolved Air Dispenser

Characteristic of LTJ Series Dissolved Gas Releaser

-Can Work Effectively Under 0.02Mpa Pressure

-Distribution Uniformity Of Effluent

-Increases the Colliding Between Micro-Bubbles and Impurities Inside the Effluent

-Generated Micro-bubble Ranges:15-30 microns

-Over 99% Releasing Efficiency

-Automatic Cleaning

-Anti-block Effectively

-Multiple Connected Pipeline: DN15-DN50

-TSS Inlet or Outlet Data Normally: 2000 or 100 mg/l

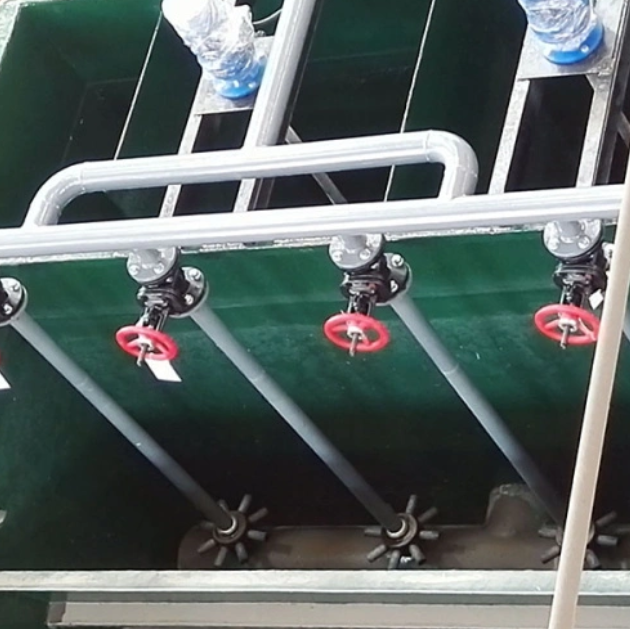

Application of Dissolved Air Flotation Machine Air Injector

-Dissolved Air Dispenser Is a Key Device In DAF Machine. Pressure Dissolved Air Water Release Lots Of Micro Bubble Only Get Through This Device.

-Aeration Pool as Aeration Injector

-Combined with Submersible Agitators or Mixers

Main Octagon Releaser Technical Parameter And Size

Model | Inlet DN (mm) | Outside size φ×H(mm) | Flow(m³/h) at 2.0-4 Mpa pressure | Effect DN mm) |

LTJ-1.25 | DN25 | 240×93 | 1.00-1.47 | 400 |

LTJ-2.50 | DN25 | 240×93 | 2.37-3.14 | 600 |

LTJ-3.50 | DN32 | 283×98 | 2.70-4.30 | 800 |

LTJ-5.00 | DN50 | 308×109 | 4.61-6.31 | 1000 |

LTJ-7.50 | DN65 | 388×123 | 6.50-8.32 | 1100 |

LTJ-10.0 | DN80 | 410×133 | 8.70-11.8 | 1200 |

Mounting Instruction

-Assure main and branch Air pipes flushed before Mounting

-Make Sure Its Vacuum End is At The Bottom When Installment

-The Ejector&Its Control Gate Layout Must Be Convenient For Operation.

-Must Be Installed horizontally to prevent uneven Flow Distribution

-Adopts An Elbow at Outlet End instead of Long Pipe if Gas line Direction Change.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.