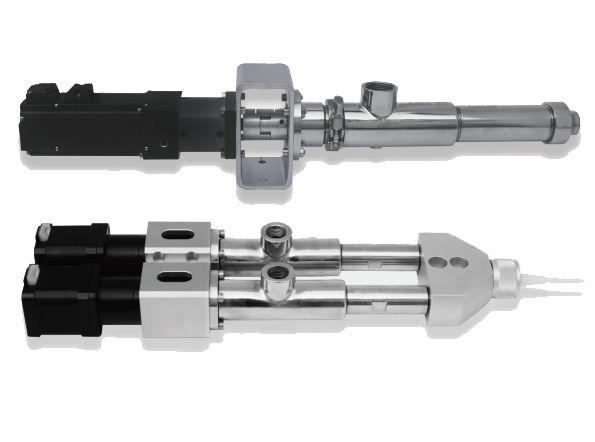

A metering pump is designed for precise and accurate dosing of fluids. It operates by moving a specific volume of liquid into a system at a controlled rate, often used in applications where exact measurement and consistency are critical. Metering pumps are commonly employed in chemical processing, water treatment, pharmaceutical production, and food and beverage industries. They offer benefits such as:

1. **Precision Dosing:** Metering pumps excel at delivering precise volumes of fluids, making them ideal for applications requiring accurate chemical dosing or additive injection.

2. **Controlled Flow:** These pumps allow for precise control over flow rates, ensuring consistent performance and product quality.

3. **Chemical Compatibility:** Many metering pumps are designed to handle a wide range of chemicals, acids, and corrosive substances, making them versatile in various industrial settings.

4. **Low Maintenance:** Due to their robust design and precise operation, metering pumps typically require minimal maintenance, resulting in reduced downtime and operational costs.

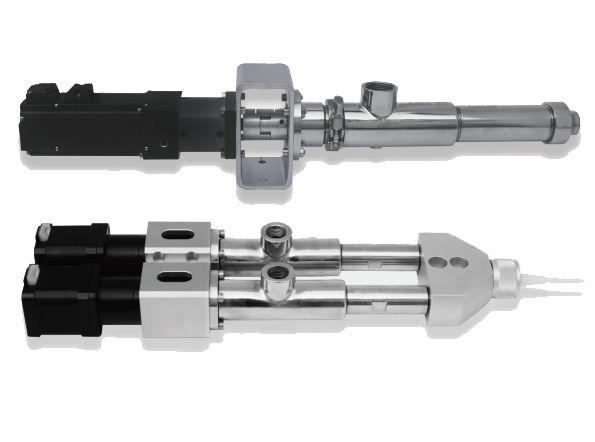

**Screw Pump:**

On the other hand, a screw pump is a positive displacement pump that uses rotating screws to move fluids through the pump. Screw pumps are known for their ability to handle viscous fluids and slurries efficiently. They are commonly used in oil and gas, wastewater treatment, marine, and industrial applications. Some advantages of screw pumps include:

1. **High Viscosity Handling:** Screw pumps are excellent at handling viscous fluids, making them suitable for applications where other pump types may struggle.

2. **Gentle Handling:** The pumping action of screw pumps is gentle, making them suitable for delicate fluids or shear-sensitive materials.

3. **Self-Priming:** Screw pumps are often self-priming, meaning they can evacuate air from the system and start pumping without external priming.

4. **Low Pulsation:** Screw pumps offer smooth and continuous flow, reducing pulsation and ensuring consistent output.

**Choosing Between Metering and Screw Pumps:**

The choice between a metering pump and a screw pump depends on the specific requirements of the application:

- **Metering pumps** are ideal for precise dosing and chemical injection tasks where accuracy and repeatability are paramount.

- **Screw pumps** excel in handling viscous fluids, slurries, and shear-sensitive materials, offering reliable performance in challenging pumping conditions.

Ultimately, selecting the right pump requires considering factors such as fluid properties, flow rates, system requirements, and industry standards to ensure optimal performance and efficiency.